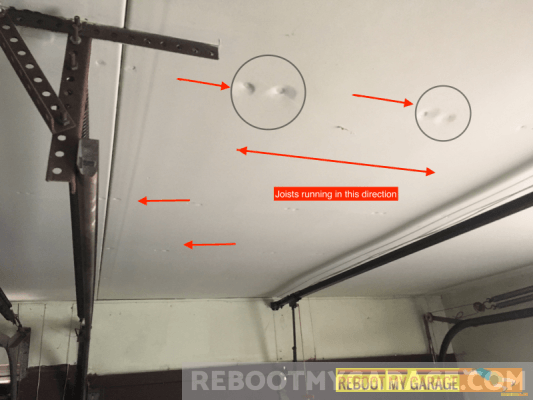

What Are Ceiling Joists (And Where to Find Them)?

Look up at your garage ceiling. The horizontal beams running parallel to each other are your ceiling joists.

These joists are the backbone of your ceiling’s structure, supporting either the roof directly or an attic floor above.

Joists typically rest on top of the garage walls. They span the entire width of the garage, transferring the weight of the roof structure down to the foundation.

In almost all residential garages, these joists are made of wood. Some modern commercial structures might use steel, but wood is the standard.

If your ceiling is finished with drywall, you’ll need a stud finder to locate these crucial support beams before mounting anything.

What Determines Your Ceiling’s Strength?

The carrying capacity of a ceiling is not a single, simple number. It depends on a complex combination of interacting factors.

First is the joist size. Common residential joists are made from 2×6, 2×8, or 2×10 lumber, and bigger is always stronger.

Next is joist spacing. They are typically spaced 16 or 24 inches on center. Closer spacing means more joists are sharing the load, resulting in a stronger overall ceiling.

The wood species and grade also play a major role. A 2×6 made of a dense species like Southern Pine is much stronger than a 2×6 of a lighter species like Spruce-Pine-Fir.

Finally, consider the span. This is the unsupported distance the joist travels between walls. The longer the span, the less weight a joist can hold without bowing or breaking.

You can see how these variables interact by looking at professional span tables, like this ceiling joist span chart, which shows how capacity changes based on these factors.

Dead Loads vs. Live Loads: What Do They Mean?

To understand your ceiling’s limits, you need to think like a structural engineer. They categorize weight into two types of loads.

A Dead Load is the constant, permanent weight of the structure itself. This includes the joists, roofing materials, drywall, insulation, and any permanent fixtures like lights or garage door openers.

A typical dead load for a roof and ceiling assembly is around 10 pounds per square foot (psf).

A Live Load is any temporary or changing weight added to the structure. This includes your stored items, people walking in the attic, or most significantly, the immense weight of snow and ice.

When a builder constructs a ceiling with a live load rating of 20 psf, that 20 psf is the budget you have for everything *except* the structure itself.

Your stored gear and any potential snow load must fit within that 20 psf budget. For detailed examples, see this structural design calculator.

The Silent Threat: How Snow Load Can Eliminate Your Storage Capacity

In regions that receive snowfall, the weight of snow on your roof is a massive “live load.” This can completely change your plans for overhead storage.

In places like Toronto or Buffalo, building codes require roofs to handle significant snow loads, often 20-40 psf or even more.

This heavy snow load consumes your ceiling’s entire live load capacity budget. The joists are already under significant stress just supporting the snow.

This leaves no meaningful capacity for you to hang heavy items from below. Adding substantial weight to a snow-loaded ceiling is extremely risky.

During winter months in snowy climates, storing anything beyond very light objects is playing with fire. The system is already at or near its design limit.

Distributed Loads vs. Point Loads: The Most Common Mistake

Understanding the difference between these two load types is critical for safety. It’s the concept most people get wrong, often with disastrous results.

A distributed load is weight that is spread out evenly across multiple joists. Think of a large overhead storage rack that is bolted to four or five different joists.

The joists work together as a system to support the weight, which is how they are designed to function.

A point load, however, concentrates the entire weight onto a very small area, often on just one or two joists. A winch, a punching bag, or an engine hoist are all examples of point loads.

A single joist is not designed to handle a heavy point load. It is designed to share a distributed load with its neighbors.

This is why hanging a 400 lb. storage rack can be safe, while hanging a 400 lb. engine block from a single eye-bolt can cause a complete structural failure.

The Heavy-Duty Winch Test: A Recipe for Disaster?

Imagine you have an electric winch capable of lifting a 2,200 lb. engine block. You plan to mount it directly to the 2×6 joists in your garage ceiling.

Is this winch safe to use to its full capacity? Based on standard building codes, the answer is an emphatic NO.

That 2,200 lb. winch creates a massive “point load.” It concentrates the entire lifting force onto the one or two joists it’s bolted to.

A single 2×6 joist cannot support 2,200 pounds under any circumstances. Attempting to do so will simply pull the joist, and a section of your ceiling, down.

Attaching a heavy winch requires significant reinforcement, such as adding extra joists (called “sistering”), cross-bracing, or even installing steel beams that transfer the load directly to the garage walls.

Without professional reinforcement, using such a winch is not a question of if it will fail, but when.

Before You Hang Anything: The Critical Ceiling Weight Question

You’re looking at that empty space above your head and thinking about storage. Maybe it’s for a heavy-duty winch, a classic car hardtop, or even just holiday decorations.

Before you drill a single pilot hole, you need to ask the most important question: how much weight can I hang from my garage ceiling?

This article contains estimates based on common building codes, but your situation is unique. Always consult a qualified structural engineer before hanging any significant loads from your ceiling.

A typical garage ceiling over an unfinished space is designed for a “live load” of 10-20 pounds per square foot (psf). This is dramatically different from the garage floor, which is rated for 50 psf to support vehicles.

This ceiling capacity is then reduced by the permanent weight of the roof structure itself (the “dead load”).

Furthermore, any potential snow on the roof (another “live load”) can consume all available capacity.

Most importantly, a heavy item concentrated in one spot, known as a “point load,” can easily cause a single joist to fail. This can happen even if the total weight is far below the distributed limit for the entire ceiling.

If your joists are spaced 24 inches apart instead of the standard 16 inches, the carrying capacity is reduced even further.

Safety First: A Critical Warning About Ceiling Weight

This information is for educational purposes only. It is not a substitute for a professional assessment of your specific garage structure.

Overloading your ceiling joists can result in catastrophic failure, leading to property damage, serious injury, or even death.

First, don’t confuse floor and ceiling ratings. Your garage floor can hold a 5,000 lb truck, but your ceiling absolutely cannot.

Remember that your ceiling is already supporting its own weight and the drywall, a “dead load” that must be subtracted from its total design capacity.

Actual load capacity varies greatly based on wood species and grade, joist size and span, and the quality of the original construction.

Even if your calculations seem to work, always leave a significant margin for safety. Never max out the theoretical capacity.

Crucially, weight must be distributed across multiple joists. Concentrating a heavy load on one or two joists is the most common cause of ceiling failure.

Before hanging anything heavier than a bicycle or a few lightweight bins, you must consult with a licensed structural engineer or a qualified contractor to ensure safety, as recommended by OSHA safety guidelines.

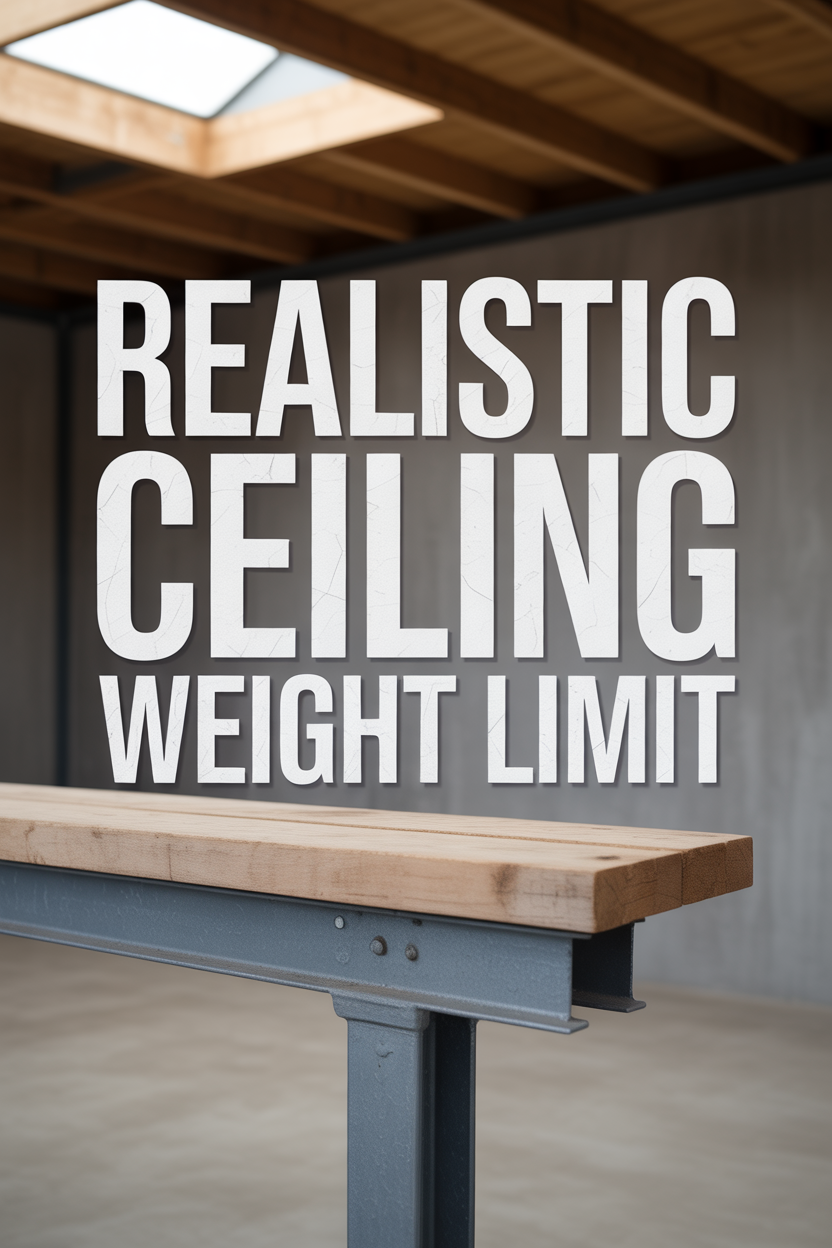

How to Estimate a Realistic Ceiling Weight Limit

The true weight capacity of your garage ceiling is measured in tens of pounds per square foot, not thousands of pounds on a single point.

Let’s calculate a more realistic limit for a common setup. Remember, the following calculations are illustrative examples. You are responsible for ensuring the safety of anything you hang from your garage ceiling.

We will use these common parameters for a 10 ft. x 10 ft. section of ceiling (100 sq. ft.):

- Structure: 2×6 Southern Pine joists, spanning 10 ft.

- Live Load Rating: 20 psf (typical for basic attic storage).

- Dead Load: 10 psf (already accounted for in the live load rating).

In an area with no snow and joists spaced 16 inches on center, your joists have their full 20 psf live load capacity available for storage.

Over a 100 sq. ft. area, this is a theoretical maximum of 2,000 lbs (20 psf x 100 sq. ft.).

However, this weight must be perfectly distributed across all the joists in that area (approximately 8 joists).

For safety, you should aim to store less than half of this theoretical amount (under 1,000 lbs) and ensure it is widely distributed.

The Impact of Spacing and Snow: Why Capacity Vanishes

Now let’s see how quickly that 2,000 lb. theoretical maximum disappears when we change the variables. The table below illustrates the dramatic effects of joist spacing and snow.

| Realistic Garage Ceiling Hanging Capacity (100 sq. ft. Area) | ||

| Scenario | Calculation | Maximum DISTRIBUTED Load |

| 16″ on Center, NO SNOW | 20 psf live load rating x 100 sq. ft. area | 2,000 lbs (spread evenly across all joists) |

| 24″ on Center, NO SNOW | Wider spacing reduces capacity by ~30%. (20 psf x 0.7) x 100 sq. ft. area |

1,400 lbs (spread evenly across all joists) |

| 16″ on Center, WITH SNOW | A 20 psf snow load uses up the entire 20 psf live load budget. (20 psf live load – 20 psf snow load) x 100 sq. ft. area |

0 lbs. The ceiling is at its design limit. |

| 24″ on Center, WITH SNOW & 2,200 lb. WinchTrying to lift 2,200 lbs with this winch creates a concentrated point load far beyond the joist’s capacity, especially with snow. This will cause a catastrophic failure. | Live load capacity is already exceeded by snow. The 2,200 lb. point load is extremely dangerous. | Severe Overload. DO NOT ATTEMPT. |

If your joists are 24 inches on center, you have fewer joists sharing the load. This reduces the distributed capacity by about 30%, dropping the theoretical maximum from 2,000 lbs to 1,400 lbs.

If you live in a snowy climate, a moderate 20 psf snow load can use up the entire 20 psf live load budget of your roof structure.

As the table shows, your available capacity for storage drops to zero. The ceiling is already doing all the work it was designed to do.

Safe and Smart Overhead Storage: What You CAN Safely Hang

After all these warnings, you might think hanging anything is a bad idea. But that’s not the case. The key is to be smart and realistic about the weight.

Hanging a 30-50 lb bicycle is a perfectly safe and reasonable load for any properly built garage ceiling. A good pulley system makes it easy to lift and lower.

Likewise, hanging a kayak, a ladder, or a few storage bins with seasonal decorations is generally safe. The crucial step is to use a storage system that distributes the weight across several joists.

For these applications, check out our guides to the Best Ceiling Rack and the Best Ceiling Bicycle Pulley.

These products are designed to mount across multiple joists, turning a potentially risky point load into a safe, distributed load.

Hanging a few hundred pounds in well-secured overhead racks is usually fine, especially in areas that don’t receive heavy snow.

The Final Verdict: When You Must Call a Structural Engineer

The materials, dimensions, and local weather all dramatically affect how much weight a garage ceiling can safely hold. A falling object doesn’t just damage property; it can be fatal.

Always leave a large margin of error in your calculations. Never push the limits of your structure.

Remember the critical difference between distributed loads (safer) and point loads (dangerous).

Hanging a bicycle is no problem. Hanging lightweight gear in a proper rack is usually fine.

But are you thinking about hanging an engine, a car hardtop, a spare axle, or using a heavy-duty winch? That is a job that absolutely requires a professional.

For any project involving heavy, concentrated loads, you must hire a licensed structural engineer to assess your garage and design a safe mounting solution. Getting it wrong is simply not an option.