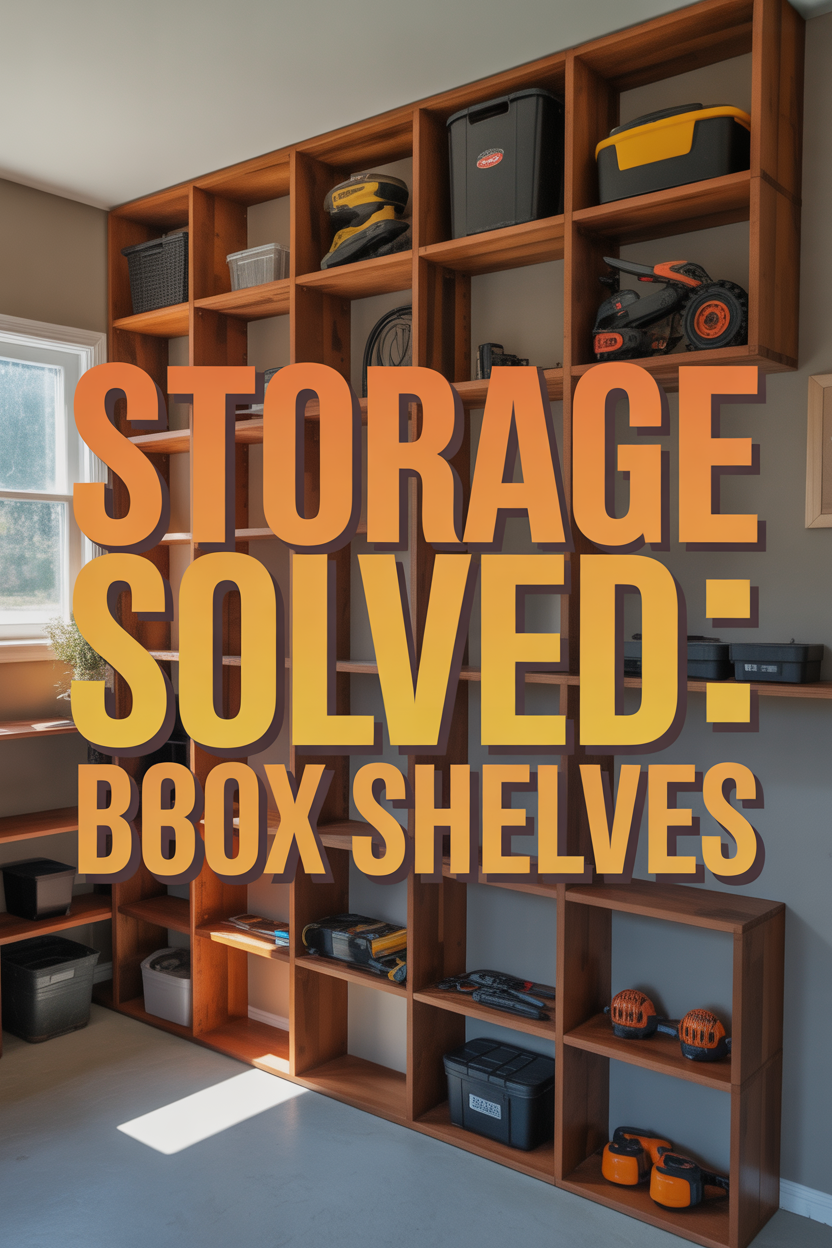

How to Build DIY Box Shelves for Ultimate Garage Organization

Is your garage looking like it was hit by a random stuff tornado? Tools lounging wherever they please, holiday decorations having a year-round party, and sports equipment playing hide-and-seek? DIY box shelves are about to become your new best friend in the battle against garage chaos. The best part? You get to build these organizational solutions yourself with basic materials and tools – custom storage that fits your unique needs!

Why Box Shelves Excel for Garage Storage

Box shelves function like the superhero version of regular shelving. Their cubby-style design creates natural dividers that keep everything in its own dedicated space.

Unlike standard open shelves where smaller items can easily fall off, box shelves keep everything contained in their own compartments.

The versatility is remarkable! You can arrange these units in countless ways to fit whatever corner or awkward space your garage presents.

When you build them yourself, you gain complete control. You can make them exactly the right size for everything from bulky power tools to those tiny hardware bits that seem to multiply when you’re not looking.

Essential Materials for Your Box Shelf Project

Before starting, gather these necessary supplies:

- Plywood (¾-inch thickness for durability)

- 2×4 lumber for frame support

- Wood screws (1¼-inch for joining plywood and 2-inch for structural support)

- Wood glue for additional strength

- Sandpaper to smooth rough edges

- Wood primer and paint/stain for protection and appearance

- L-brackets for wall mounting

- Wall anchors appropriate for your garage walls

For a standard 3×3 box shelf unit with 9 cubbies, you’ll typically need about two 4×8-foot sheets of plywood. Measure your space carefully before purchasing materials.

Tools You’ll Need for Successful Construction

These everyday tools will help you complete your project efficiently:

- Circular saw or table saw for cutting plywood

- Drill with assorted screwdriver bits

- Measuring tape for accurate dimensions

- Carpenter’s square to ensure right angles

- Level to maintain proper alignment

- Sanding block or electric sander

- Clamps to hold pieces while working

- Safety equipment (eye protection, hearing protection, dust mask)

- Pencil for marking measurements

If you’re missing some tools, consider borrowing from neighbors or renting from local hardware stores to keep costs down.

Designing Your Custom Box Shelf System

Proper planning leads to successful execution:

First, measure your available wall space carefully, checking twice to confirm accuracy.

Take inventory of what needs storage space and measure your largest items to ensure proper fit.

Decide how many cubbies you need based on your storage requirements.

Sketch your design with all dimensions, including the plywood thickness in your calculations.

Most garage storage cubbies work well at 12-18 inches in each dimension, but customize based on your specific needs.

Consider making some cubbies larger than others! Your garden tools need more space than paint cans. Varied sizes create a more functional storage system.

Cutting Your Materials with Precision

Accurate cutting ensures your shelves fit together properly:

Transfer your design plans to the plywood using a carpenter’s square to maintain straight lines.

Label each piece clearly as you cut them – this saves confusion during assembly.

Set your saw depth slightly deeper than your plywood thickness to avoid damaging your work surface.

Cut with the good side down to minimize splintering on visible surfaces.

Use a straight edge guide for long cuts to maintain accuracy.

Sand all edges smooth to prevent splinters and improve the finished appearance.

Many hardware stores offer cutting services, sometimes for free or a small fee, which can be helpful if you’re new to woodworking.

Choosing the Right Assembly Methods

Different fastening techniques offer varying benefits:

Screws: Provide strong connections and can be removed if adjustments are needed. Always pre-drill to prevent wood splitting. Use 1¼-inch screws for joining plywood pieces.

Nails: Offer quick installation but less holding power than screws. If using nails, choose finishing nails and use them generously for adequate strength.

Wood Glue: Creates excellent bonds when used with mechanical fasteners. Apply a thin, even layer, clamp until dry, then add screws or nails for maximum durability.

For garage shelves that will hold significant weight, combine wood glue with screws for the strongest possible connection.

Ensuring Level, Square Construction

Proper alignment creates stable, professional-looking shelves:

Assemble on a flat, level surface to prevent warping or misalignment.

Use corner clamps to maintain perfect 90-degree angles during assembly.

Check for square corners by measuring diagonally from corner to corner – both measurements should match exactly.

Use your level frequently throughout construction to ensure everything remains properly aligned.

Consider adding a backing board to larger units to prevent racking (sideways movement).

For freestanding units, adjustable feet can compensate for uneven garage floors.

Finishing Touches for Durability and Style

Proper finishing improves both appearance and longevity:

Sand all surfaces progressively, starting with medium-grit and finishing with fine-grit sandpaper.

Slightly round sharp edges and corners to prevent injury and chipping.

Remove all dust with a tack cloth before applying finishes.

Apply wood primer to ensure proper paint adhesion and coverage.

Choose semi-gloss or gloss paint for easier cleaning in the garage environment.

Consider a polyurethane topcoat for additional protection against spills and moisture.

For visual organization, paint cubby backs in different colors to create an intuitive storage system. Lighter colors also improve visibility when searching for items.

Professional Installation Techniques

Secure mounting ensures safety and stability:

Locate wall studs using a stud finder before installation.

Position your shelving unit with assistance, checking for level before marking attachment points.

Attach L-brackets to both the shelf unit and wall studs for maximum stability.

Secure freestanding units to walls with safety straps to prevent tipping.

Use appropriate anchors if stud attachment isn’t possible, though direct stud mounting provides the best support.

For concrete garage walls, use masonry anchors and a hammer drill for proper installation.

Creative Configuration Ideas

Maximize your garage space with these innovative designs:

- Corner Storage Units: L-shaped designs that utilize awkward corner spaces

- Ceiling Height Units: Tall configurations that take advantage of vertical space

- Under-Workbench Storage: Slide-out box shelves that use otherwise wasted space

- Mobile Storage Units: Adding heavy-duty casters for flexibility and convenience

- Modular Storage Designs: Smaller units that can be rearranged as needs change

The most effective garage systems combine both fixed and flexible storage options to accommodate changing needs.

Creating an Effective Organization System

Make the most of your new shelves with a practical organization strategy:

- Group similar items together for logical access

- Use clear containers within cubbies for smaller items

- Create waterproof labels that resist garage moisture

- Implement a color-coding system for quick visual identification

- Take photos of bin contents for easy reference

- Leave some empty space to accommodate future items

The best organization system is simple enough for everyone in your household to follow consistently.

Cost Benefits: DIY vs. Store-Bought Solutions

Building your own box shelves offers significant financial advantages:

For a standard 3×3 box shelf unit with 9 cubbies, expect these approximate costs:

- DIY Box Shelf Materials: $75-125 depending on wood quality and finish choices

- Store-Bought Equivalent: $150-300 for comparable quality and size

- Professional Installation: $400-800 for custom-built units

Beyond cost savings, DIY shelves provide the benefit of perfect customization for your specific space and storage needs.

Your exact costs will vary based on current lumber prices and the finishing materials you select.

Maintenance for Long-Term Performance

Keep your box shelves functioning well for years with these maintenance practices:

- Check and tighten all hardware annually

- Monitor for moisture issues, especially in humid climates

- Touch up paint or sealant at the first sign of wear

- Dust regularly to maintain cleanliness

- Handle shelves carefully to avoid surface damage

- Apply furniture wax periodically for easier cleaning and protection

With proper care, your DIY box shelves will provide reliable storage for many years, making your initial time investment well worthwhile.

With some basic tools, quality materials, and a weekend of work, you can transform your cluttered garage into an organized space where everything has its place. The satisfaction of knowing exactly where to find your tools and supplies is truly priceless!

Understanding Weight Capacity Limits

Properly built ¾-inch plywood box shelves typically support 30-50 pounds per cubby. For storing heavier items:

- Add extra vertical dividers to increase weight capacity

- Reinforce shelf bottoms with 1×2 support strips

- Distribute weight evenly across the unit

- Place heavier items in lower cubbies for better stability

- Secure wall-mounted units directly to studs rather than using drywall anchors

Always build with a safety margin, engineering your shelves to hold more weight than you expect them to bear.