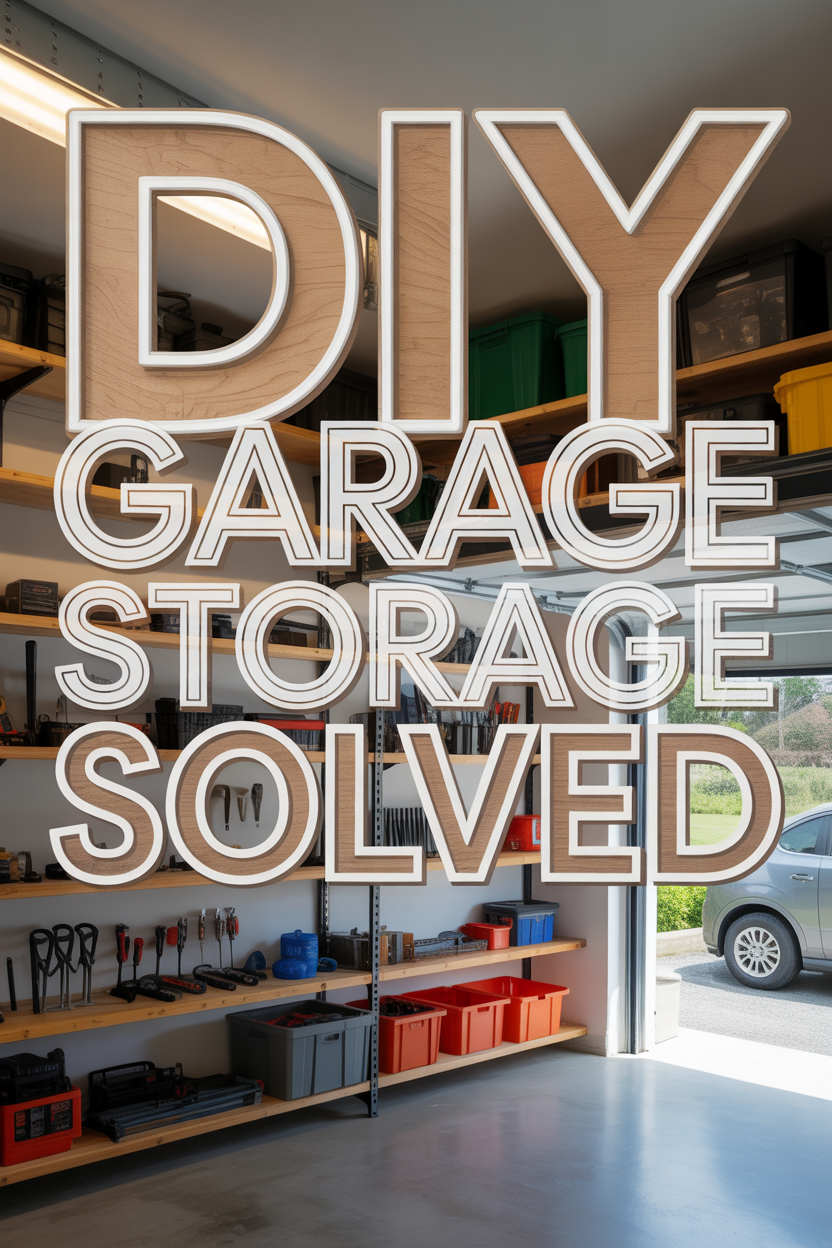

DIY Plywood Garage Shelves: The Complete Guide to Organizing Your Space

Drowning in garage clutter? Don’t worry—salvation is just a few pieces of plywood away! With some basic tools and a free weekend, you can create custom plywood garage shelves that’ll make your neighbors wonder if you’ve secretly hired a professional organizer. I’m grinning just thinking about your future gloriously organized space! Let’s dive into this step-by-step guide that’ll take you from “where’s my stuff?” to “wow, look at my stuff!”

Why Plywood is Ideal for Garage Shelving

Plywood is the perfect material for garage shelving projects. First off, it has an impressive strength-to-weight ratio. Unlike solid wood that might warp when exposed to changing conditions, plywood’s cross-laminated structure distributes weight evenly, keeping everything nice and straight. It’s also more dimensionally stable than solid wood, meaning it won’t react dramatically to temperature or humidity changes—a huge plus for garage environments!

Your wallet will thank you too! Plywood delivers serious structural integrity without requiring a major investment. Plus, those large 4′ x 8′ sheets mean you can maximize material usage with minimal waste.

And talk about versatility! Plywood comes in various thicknesses and grades to suit different storage needs. Whether you’re storing lightweight holiday decorations or heavy tools, there’s a plywood thickness perfect for your garage organization system.

Tools and Materials You’ll Need for DIY Plywood Shelves

Here’s what you’ll need to gather before starting your project:

Tools:

- Circular saw or table saw

- Drill with bits

- Measuring tape

- Level

- Stud finder

- Square

- Sanding block or electric sander

- Safety equipment (goggles, ear protection, dust mask)

- Pencil

- Clamps

Materials:

- Plywood sheets (¾” thickness recommended)

- 2×4 lumber

- Wood screws (1¼” for plywood, 3″ for frame)

- Wood glue

- Sandpaper

- Finish of choice (paint, stain, or sealer)

- L-brackets or shelf brackets

- Wall anchors

Measuring and Planning Your Garage Shelving System

Proper planning prevents poor performance! Start by taking inventory of what’s going into storage. Different items require different shelf dimensions.

Grab your measuring tape and map your garage walls carefully. Note every outlet, switch, and architectural feature. Most importantly, measure with your cars parked inside to ensure your shelves won’t interfere with vehicle doors or movement.

For shelf depth, 12″ works for smaller items while 24″ accommodates larger storage containers. Height-wise, remember that shelves placed too high become difficult to access and less practical.

Draw a rough sketch of your garage with the proposed shelving layout. This will help you calculate materials needed and identify potential problems before they occur. This simple planning step can save hours of troubleshooting later!

How to Choose the Right Plywood Grade for Garage Shelves

Plywood grades can be confusing until you understand what you actually need:

A-Grade: This highest quality plywood has a flawless appearance but is unnecessarily expensive for most garage shelving projects.

B-Grade: Has a nice appearance with minimal flaws. Good if appearance matters to you or if shelves will be visible to guests.

C-Grade: Contains some knots and patches but provides solid structural integrity. Ideal for painted garage shelves and much more affordable.

D-Grade: Rough appearance but structurally sound. Perfect if functionality matters more than appearance.

For most garage shelving projects, BC or CD plywood offers the best balance between appearance and cost. Remember, the first letter indicates the front face quality, while the second is the back face.

Besides grade, consider these plywood types:

Sanded Plywood: Smooth surface that’s ideal if you plan to paint your shelves.

Exterior Plywood: Contains water-resistant glue—a smart choice for garages with humidity issues.

Pressure-Treated Plywood: Resistant to rot and insects but more expensive and contains chemicals. Usually unnecessary for indoor garage applications.

For most garage shelving projects, ¾” standard sanded plywood provides the perfect balance of strength, weight, and cost.

Step-by-Step Guide to Cutting Plywood for Your Shelves

Now it’s time to transform those large sheets of plywood into custom shelving components:

1. Create a cutting plan: Map your cuts on paper first to maximize material use and minimize waste.

2. Mark your measurements: Use a pencil and straight edge to clearly mark all cut lines. Label which pieces you’re keeping to avoid confusion.

3. Set up a cutting station: Support your plywood evenly on sawhorses with scrap wood underneath the cutting line for cleaner cuts and better stability.

4. Prevent splintering: To minimize tear-out, place the good side down when using a circular saw. The upward rotation of the blade will splinter the bottom, not the top.

5. Make the cuts: Clamp a straight edge guide to the plywood to guide your saw. Take your time and maintain steady pressure. Let the saw reach full speed before starting each cut.

6. Sand the edges: Fresh-cut plywood edges can be rough and splintery. A quick sanding makes everything safer to handle and more professional-looking.

If precision cutting makes you nervous, many home improvement stores offer cutting services for a small fee. This can be a good option if you’re concerned about making accurate cuts.

Building a Basic Plywood Shelf Frame

Let’s create a sturdy framework to support your shelves:

1. Create a base frame: Cut your 2x4s to form a rectangular frame. For an 8′ shelf, you’ll need two 96″ pieces for front and back, plus side pieces and middle supports to complete your rectangle.

2. Assemble the frame: Lay everything out on a flat surface. Apply wood glue to the joints, then secure with 3″ wood screws. Pre-drilling holes prevents the wood from splitting.

3. Add cross supports: For shelves longer than 4′, add cross supports every 16-24″ to prevent sagging under weight. Attach these just like you did the corner joints.

4. Check for square: Measure diagonally from corner to corner in both directions. If the measurements match, your frame is square. If not, adjust until the measurements are equal.

5. Attach the plywood top: Spread wood glue on the frame edges, then place your cut plywood on top. Secure with 1¼” screws every 8-12″ around the perimeter and along supports.

For multi-tier shelving units, repeat this process for each level, then connect them using vertical 2×4 supports. Each shelf you add multiplies your storage capacity!

Wall-Mounted vs. Free-Standing Plywood Shelving Units

There are two main approaches to garage shelving. Let’s compare them:

Wall-Mounted Shelves:

- Advantages: Frees up valuable floor space, typically more stable when properly installed, height-adjustable, and utilizes otherwise unused wall areas.

- Disadvantages: Requires proper wall anchoring into studs, more complex installation, and limited by wall structure.

- Best for: Garages where floor space is at a premium, storing items you access frequently, and keeping tools at convenient heights.

Free-Standing Shelves:

- Advantages: Movable when you need to reconfigure your space, often handles heavier loads, and doesn’t require finding wall studs.

- Disadvantages: Takes up floor space, can wobble if not properly built, and requires more materials than wall-mounted options.

- Best for: Heavy storage items, frequently reorganized spaces, and rentals where wall modifications might not be allowed.

Many well-organized garages use a combination approach! Wall-mounted shelves for frequently used items and tools, with free-standing units for heavier seasonal storage.

For maximum stability in free-standing units, consider adding diagonal braces at the back or anchoring the top to wall studs while keeping the structure floor-supported.

Adding Support Brackets for Extra Strength

Support brackets significantly increase the strength and stability of your shelves:

For Wall-Mounted Shelves:

- Use a stud finder to locate wall studs. This is critical for proper support.

- Install heavy-duty L-brackets into the studs every 16-24″. Drywall alone cannot support loaded shelves.

- Choose brackets rated for at least 25% more weight than you plan to store to provide a safety margin.

- Secure your shelves to the brackets with screws through pre-drilled holes for maximum stability.

For Free-Standing Units:

- Add corner braces where shelves meet vertical supports to prevent wobbling.

- Install L-brackets under each shelf at connection points for added reinforcement.

- For shelves longer than 4′, add center support brackets to prevent sagging under weight.

Additional Support Options:

- Metal shelf standards and brackets allow for adjustable heights as your storage needs change.

- Diagonal braces at 45° angles dramatically increase stability.

- For extremely heavy loads, consider doubling the plywood thickness or adding steel reinforcement strips underneath.

Remember that connection points are where most shelving systems fail first. Using quality hardware and ensuring tight connections will prevent future failures and collapse.

Finishing Your Plywood Shelves: Sanding and Sealing

Proper finishing extends the life of your shelves while improving their appearance:

Sanding Process:

- Start with medium-grit sandpaper (80-100 grit) to smooth rough surfaces.

- Progress to finer grit (120-150) for a smoother finish.

- Pay special attention to edges and cut ends where splinters are most likely.

- Always sand with the grain direction to avoid visible scratch marks.

- Wipe everything with a tack cloth to remove dust before applying finish.

Sealing Options for Garage Shelves:

- Polyurethane: Excellent moisture protection and durability. Oil-based versions offer superior protection but have stronger odors and longer drying times. Water-based options dry faster with less odor.

- Shellac: Dries very quickly and provides a warm appearance but offers less moisture protection than other options.

- Danish oil: Easy to apply (just wipe on, wait, wipe off) and enhances wood grain while providing moderate protection.

- Wood sealer: Basic protection focused on keeping moisture out rather than appearance enhancement.

For garage environments, apply at least two coats of sealer, with a light sanding between coats. This creates a stronger protective barrier against humidity, spills, and wear over time.

Paint or Stain? Best Finishes for Garage Shelves

Choosing between paint and stain depends on your priorities:

Paint for Garage Shelving:

- Advantages: Completely seals the wood, hides imperfections in the plywood, comes in unlimited color options, and wipes clean easily.

- Disadvantages: Conceals the natural wood appearance, can chip over time, and requires primer for best results.

- Best choice: Semi-gloss or satin latex paint with primer underneath. The slight sheen makes dust and dirt more visible and easier to clean.

Stain for DIY Plywood Shelves:

- Advantages: Enhances natural wood grain, penetrates the wood rather than sitting on top, less likely to chip, and generally easier to apply.

- Disadvantages: Provides less protection than paint, shows every imperfection, and offers fewer color options.

- Best choice: Oil-based stain followed by polyurethane topcoat for both appearance and protection.

Clear Finish for Storage Shelves:

- Advantages: Preserves wood’s natural appearance, protects against moisture without changing color, and comes in various sheen levels.

- Disadvantages: Shows all of the wood’s character and flaws, provides less visible evidence of protection, and may require more maintenance over time.

- Best choice: Water-based polyurethane for easy application and cleanup.

For most garage shelving projects, paint offers the best protection-to-effort ratio. Choose light colors to brighten your garage and make stored items easier to find. If you prefer a natural wood appearance, use a stain with several polyurethane topcoats for protection.

Maximizing Storage Space with Adjustable Shelving

Flexibility is key to effective garage organization. Here’s how to make adaptable shelves:

Track and Bracket Systems:

- Install vertical metal tracks (standards) on wall studs.

- Use compatible brackets that slide into the tracks and can be repositioned without new holes.

- Place your plywood shelves on these brackets for easily adjustable storage.

- This system lets you reconfigure your shelves as your storage needs change over time.

Peg and Hole System:

- Create vertical supports with evenly spaced holes.

- Use shelf pins or pegs that insert into these holes to support shelf edges.

- This traditional approach requires precise drilling but offers many adjustment options.

Modular Design for Garage Organization:

- Build separate stackable units that can be rearranged as needed.

- Use consistent dimensions so components work together seamlessly.

- This approach lets you add, remove, or rearrange entire sections as your storage needs change.

Space-Maximizing Tips for DIY Plywood Shelves:

- Vary shelf spacing based on what you’re storing—narrower spaces for small items, wider gaps for larger containers.

- Consider ceiling-mounted shelving for seasonal or rarely used items.

- Add vertical dividers to separate items and prevent storage avalanches.

- Attach hooks or pegs to the underside of shelves to utilize that otherwise unused space.

Label your shelves and storage containers clearly to make finding items easier. A simple organization system prevents frustration and wasted time searching for specific items.

Weight Considerations: How Much Can Plywood Shelves Hold?

Understanding weight limits is crucial for safe and effective storage:

Plywood Thickness for Garage Shelving:

- ½” plywood: Suitable only for light items like empty containers or paper goods.

- ¾” plywood: Standard for most garage storage (20-40 lbs per square foot). Handles typical garage items effectively.

- 1″ plywood: For heavy-duty storage needs like automotive parts, tools, or construction materials.

Span Distance for DIY Shelves:

The distance between supports significantly affects weight capacity:

- 12″ span: ¾” plywood can hold 50+ lbs/sq.ft without sagging.

- 24″ span: ¾” plywood can handle 30-40 lbs/sq.ft before showing signs of stress.

- 36″ span: Weight capacity drops to 20-30 lbs/sq.ft with visible bending under load.

- 48″ span: Significant sagging occurs even with minimal weight.

Support Structure for Garage Organization:

- Frame design dramatically affects overall strength—box frames with cross supports provide maximum stability.

- Quality brackets are essential—inexpensive brackets may fail under real-world loads.

- Wall-mounted shelves depend entirely on proper stud connection for their stability and strength.

Weight Distribution on DIY Plywood Shelves:

- Evenly distributed weight causes less stress than concentrated weight in one area.

- Place heavy items directly above supports rather than in the middle of unsupported spans.

- Frequently accessed items require additional strength margins as repeated loading and unloading stresses connections over time.

For typical garage storage, ¾” plywood with supports every 24″ will safely hold tools, paint cans, and general household items. For automotive parts, batteries, or exercise equipment, reduce the span to 16″ or use thicker plywood.

Common Mistakes to Avoid When Building Garage Shelves

Learn from these common errors to ensure your shelving project succeeds:

Planning Errors for DIY Shelves:

- Failing to measure garage space accurately. Precise measurements are essential for proper fit.

- Forgetting that nominal lumber dimensions differ from actual dimensions (a 2×4 isn’t actually 2″ by 4″).

- Underestimating item weight when planning shelf capacity.

- Making shelves too deep, creating hard-to-reach spaces at the back.

Construction Mistakes for Garage Storage:

- Using drywall screws for construction. They’re designed for drywall, not load-bearing structures.

- Attaching shelves to drywall alone instead of studs. Drywall cannot support significant weight.

- Skipping pre-drilling, which often results in split wood.

- Not checking for square during assembly, resulting in unstable, wobbly shelves.

- Inadequate bracket spacing that leads to sagging shelves under load.

Material Misjudgments for Storage Shelves:

- Choosing plywood that’s too thin for the intended load.

- Using indoor materials in potentially damp garage environments.

- Skipping the finishing step, which protects wood from moisture and damage.

- Using low-quality brackets that may fail under weight.

Safety Oversights with DIY Garage Shelves:

- Neglecting safety gear during construction (eye protection, dust masks, etc.).

- Overloading shelves beyond their weight capacity.

- Placing the heaviest items on top shelves where they’re harder to access safely.

- Building shelves that block electrical panels, water heaters, or safety equipment.

Take your time during both planning and building phases. Proper preparation prevents many common problems and ensures your shelves will be both functional and durable.

Budget Breakdown: Cost of DIY vs. Store-Bought Shelves

Understanding the financial aspects helps you make informed decisions:

DIY Plywood Shelving Costs (for a typical 8’×4′ three-shelf unit):

- Plywood (2 sheets of ¾” plywood): $80-120

- 2×4 lumber for framing: $30-45

- Hardware (screws, brackets): $20-40

- Finish materials (sandpaper, paint/sealer): $15-30

- Total DIY garage shelves cost: $145-235

Store-Bought Shelving Options for Garage Organization:

- Basic metal utility shelving (48″×24″): $80-150 per unit

- Heavy-duty commercial shelving: $200-350 per unit

- Pre-made wooden shelving units: $250-500 per unit

- Custom-built shelving (professionally installed): $500-1,000+ per unit

Cost-Benefit Analysis of DIY Plywood Garage Shelves:

- DIY advantages: Custom dimensions to fit your specific space, higher quality materials than many commercial units, and the satisfaction of creating something yourself.

- Store-bought advantages: No specialized tools required, immediate installation, and consistent appearance.

Hidden Costs to Consider for Garage Shelving:

- Tool purchases or rentals if you don’t already own necessary equipment.

- Value of your time (typically 10-20 hours for a complete shelving project).

- Delivery costs for materials or pre-made units.

- Potential waste from cutting errors or miscalculations.

For most homeowners, DIY plywood garage shelves offer better value—especially if you already have basic tools and enjoy hands-on projects. The savings become even more significant when building multiple units or custom configurations that would be expensive to purchase pre-made.

Maintenance Tips to Make Your Plywood Shelves Last Longer

Proper maintenance extends the life of your shelving investment:

Regular Inspection of Garage Shelving:

- Check for shelf sagging, especially in the middle sections.

- Inspect brackets and supports for loose screws or connections.

- Look for moisture damage, particularly near exterior walls.

- Tighten loose connections immediately to prevent worsening problems.

Cleaning Practices for DIY Plywood Shelves:

- Dust shelves regularly to prevent buildup.

- Clean spills promptly, especially automotive fluids or chemicals.

- For sealed shelves, a damp cloth with mild detergent works well for regular cleaning.

- Allow shelves to dry completely before replacing items to prevent moisture damage.

Preventing Damage to Garage Storage:

- Use shelf liners where tools or metal objects are stored to prevent surface scratches.

- Place heavy items directly over supports rather than in unsupported middle sections.

- Use plastic bins instead of cardboard boxes for long-term storage in garage environments.

- Lift items rather than dragging them across shelf surfaces to prevent damage.

Long-Term Care for DIY Plywood Garage Shelves:

- Reapply finish every 2-5 years depending on garage conditions.

- Address finish damage promptly with touch-ups to prevent moisture penetration.

- Redistribute weight if you notice even minor sagging developing.

- Add supports if your storage needs become heavier over time.

Garage environments can be harsh with temperature fluctuations and humidity changes. Regular maintenance prevents small issues from becoming major problems and extends the useful life of your shelving system.

By following this comprehensive guide, you’ll create DIY plywood garage shelves that transform your space from cluttered chaos to organized efficiency. The investment of time and materials will reward you with better accessibility, protection for your belongings, and the satisfaction of a well-organized garage. Happy building!