The Great Garage Insulation Debate: Batt vs. Rigid Foam

Walk into many unfinished garages, and you’ll see walls of exposed studs filled with fluffy insulation. It’s a common sight, but it raises an important question: what’s the best way to keep your garage comfortable?

When it comes to the great insulation debate, which side are you on? The classic, fluffy batt insulation or the newer, sleek rigid foam boards?

There’s no single right answer. Your choice depends on your budget, how you use your garage, and how much space you have in your walls. While batt insulation is a DIY-friendly favorite, rigid foam brings serious insulating power in a slim package.

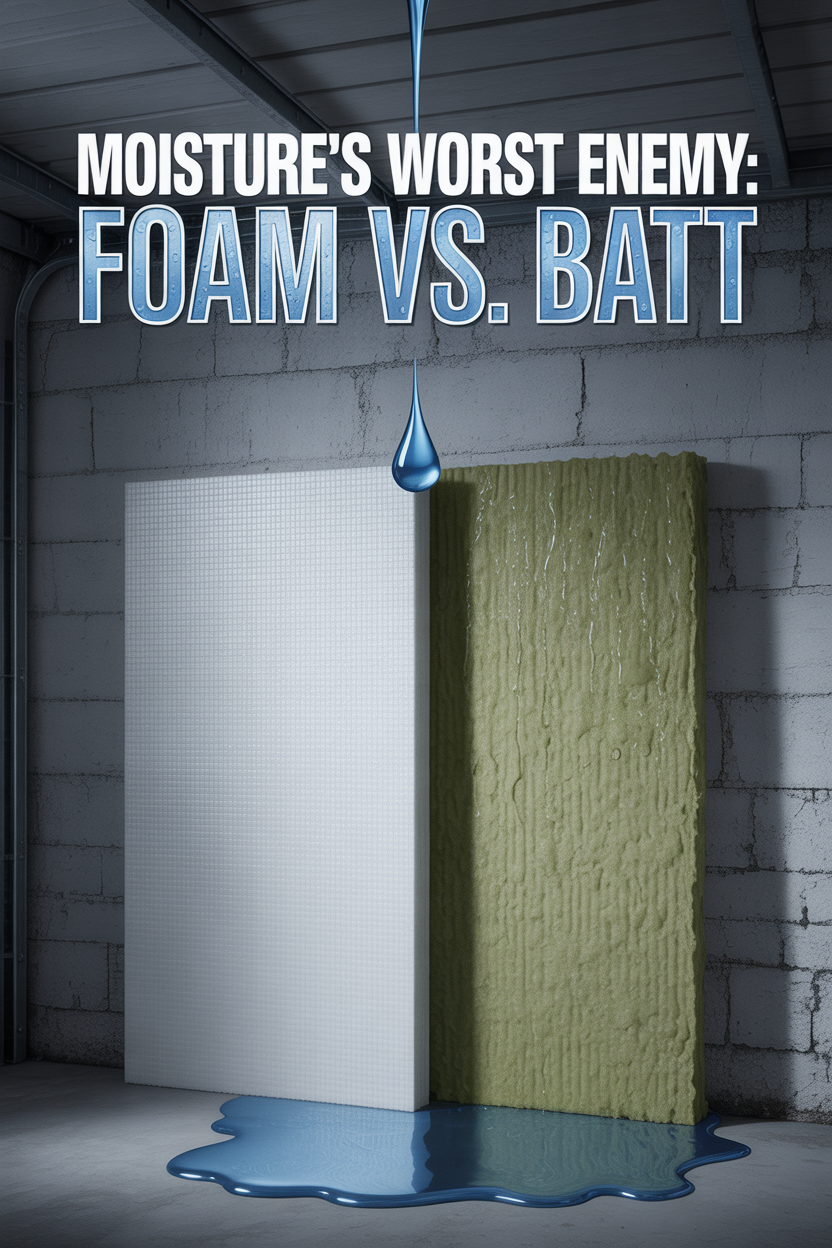

For example, rigid foam is completely waterproof, making it perfect for damp areas. Batt insulation, however, stops working the moment it gets wet or compressed. Let’s dive into the details to help you find the perfect fit for your garage.

Decoding R-Value: Which Insulation Performs Best?

When comparing R-value—the measure of an insulation’s ability to resist heat flow—per inch of thickness, high-quality foam board clearly has the edge. This is the single most important metric for pure thermal performance.

In terms of insulation value per inch, the materials rank from most to least insulating as follows:

- Polyisocyanurate (polyiso) foam board: R-6.0 to R-6.5 per inch

- Extruded polystyrene (XPS) foam board: R-5.0 per inch

- Mineral wool batt: R-4.3 to R-4.7 per inch

- Expanded polystyrene (EPS) foam board: R-3.6 to R-4.2 per inch

- Fiberglass batt: R-3.2 to R-3.8 per inch

This list shows that a specific material’s performance is more important than whether it’s batt or foam. However, batt insulation is typically made in greater thicknesses (like 3.5″ or 5.5″).

This means a single batt often provides a high total R-value (R-13 to R-23) right out of the package. To get an equivalent R-value from foam board, you often need to layer multiple sheets, which can increase labor and cost.

For a detailed comparison, check out this guide on choosing between foam board and batt.

What is Batt Insulation? A DIY-Friendly Choice

Batt insulation is the classic, fluffy insulation you’re likely picturing. It’s sold in pre-cut rectangular pieces or long, continuous rolls designed to fit perfectly between standard stud and joist spacing (typically 16 or 24 inches).

This “friction-fit” design makes it a favorite for do-it-yourself projects, as it’s relatively easy to handle and install in open wall cavities.

Batt insulation is most commonly made from fiberglass or mineral wool. However, you can also find it made from other materials like plastic fibers or natural fibers such as cotton (denim).

Fiberglass vs. Mineral Wool: A Batt Insulation Breakdown

Both fiberglass and mineral wool are popular choices for batt insulation, but they have distinct differences in performance and handling.

Fiberglass batt uses fine glass fibers that can cause skin and respiratory irritation, so you must always wear protective gloves, a mask, and goggles when handling it. Its R-value is determined by its density: a standard 3.5″ batt can range from R-11 (low-density) to R-15 (high-density).

Mineral wool is made from molten minerals, like volcanic rock (rock wool) or industrial slag (slag wool). It offers a slightly higher R-value than fiberglass per inch; a 3.5″ batt is typically R-15, and a 5.5″ batt is R-23.

While fiberglass is less expensive and more widely available, mineral wool is denser, less irritating to work with, and far superior in fire and moisture resistance. Mineral wool also provides excellent sound dampening, making it a great choice for a garage workshop.

For pure performance, mineral wool has clear advantages. But if budget is your main constraint, fiberglass remains a smart, cost-effective option.

Where Should You Use Batt Insulation in Your Garage?

The ideal place for batt insulation is within open-framed structures. Think of the spaces between wall studs and ceiling joists in an unfinished garage.

It’s designed to be cut and fitted snugly into these cavities. This straightforward installation process is what makes it so appealing for DIYers.

When installing, it’s crucial not to compress the batt, as this crushes the air pockets that provide its insulating power and reduces the R-value. Unfaced batts are held by friction, while faced batts have paper flanges that you staple to the sides of the studs.

You can also use batt-style insulation on the garage door itself. Many garage door insulation kits use pre-cut batt panels that are held in place with special pins or adhesives within the door’s channels.

What Is Rigid Foam Board Insulation?

Foam board insulation is a rigid panel made from plastic polymers. Unlike fluffy batt, it is dense, durable, and provides a high R-value in a slim profile.

It’s worth noting that most foam boards are not biodegradable and can pose environmental concerns. There are three main types you’ll encounter at the hardware store.

- Expanded Polystyrene (EPS): This is the white, beaded foam you see in coolers. It’s the most affordable rigid foam, offering an R-value of R-3.6 to R-4.2 per inch.

- Extruded Polystyrene (XPS): Usually blue or pink, XPS is denser and more durable than EPS. It provides an R-value of about R-5 per inch and has better moisture resistance.

- Polyisocyanurate (Polyiso): Often foil-faced, polyiso delivers the highest R-value of common rigid foams, with an R-value of R-6.0 to R-6.5 per inch. The foil facing also acts as a built-in radiant and vapor barrier.

How to Compare Foam Boards: EPS, XPS, and Polyiso

Choosing the right foam board comes down to balancing performance and cost for your specific project.

Polyiso is the champion for R-value per inch. Its built-in foil face provides a radiant and vapor barrier, making it an all-in-one solution for maximizing thermal resistance in tight spaces.

XPS offers a great middle-ground. It has a strong R-value, good compressive strength, and better moisture resistance than EPS, making it a durable and reliable choice for garage walls.

EPS is the most economical option. While it has the lowest R-value of the three, its low cost makes it perfect for projects where you need to cover a large area and can stack multiple layers to achieve your desired total R-value.

Remember, you can and often should stack layers of foam board. For example, two layers of 1-inch polyiso board will give you a total R-value of around R-13, equivalent to a standard fiberglass batt but in just two inches of thickness.

Do You Need a Vapor Barrier With Your Insulation?

A vapor barrier is a crucial, yet often misunderstood, part of a complete insulation system. The decision to use one depends entirely on your climate and the space next to your garage.

If there’s a big temperature and humidity difference between your garage and an adjoining room or the outdoors, a vapor barrier is essential. It prevents warm, moist air from getting into the wall, where it can condense and lead to mold and rot.

Many insulation products come with a built-in vapor barrier (more accurately, a vapor retarder). Kraft-faced (paper-backed) batt insulation and foil-faced polyisocyanurate foam are two common examples.

If you use unfaced batt or other foam types like EPS or XPS, you will need to install a separate plastic sheeting barrier.

Always install the vapor barrier on the “warm side” of the insulation. In a cold climate where you’ll be heating your garage, this means the paper, foil, or plastic sheeting should face into the garage space.

Which Insulation Handles Moisture Best?

When it comes to moisture, rigid foam has a clear advantage over batt insulation. Foam panels, particularly XPS and foil-faced polyiso, are highly resistant to water.

If they get wet, they do not absorb water, will dry out, and will retain their original R-value. This makes them the superior choice for any area prone to dampness, like basements or concrete block garage walls.

Wet batt insulation, on the other hand, is a catastrophe. It compresses under the weight of water, completely losing its insulating air pockets and thermal resistance.

Worse, saturated batt insulation becomes a breeding ground for mold and mildew, which can harm your garage’s air quality and lead to wood rot in your walls. If your batt gets wet, you must fix the source of the leak and replace the insulation itself.

Even when using foam, you must address any moisture issues. Preventing water from getting in is key to the long life of your entire wall system.

Durability and Longevity: Batt vs. Foam Board

Beyond moisture, the key factor in insulation durability is compression. Compression is the ultimate enemy of batt insulation.

If you crush, stuff, or tightly pack batt insulation to fit into a space, you eliminate the air pockets that give it its insulating power. Its R-value will drop significantly.

Rigid foam board does not have this problem. Its dense, solid structure ensures it maintains its R-value even under pressure, making it a far more durable and foolproof product in this respect.

While carefully installed batt insulation can perform well for decades, the natural durability of rigid foam provides greater peace of mind. Its resistance to compression and moisture means its performance is locked in from day one.

The Real Cost: A Dollar-for-Dollar Comparison

While foam board might seem cheaper per sheet, a true cost comparison requires looking at the cost per R-value point. This tells you how much you’re paying for each unit of insulating power.

To find this, simply divide the price of the product by the total R-value it provides.

For example, let’s say an R-13 fiberglass batt costs $1.00 per square foot. Its cost is 7.7 cents per R-value point ($1.00 / 13).

Now consider a 1-inch R-6 polyiso board that costs $0.80 per square foot. To get close to R-13, you’d need two layers, for a total of R-12 at a cost of $1.60 per square foot. This works out to 13.3 cents per R-value point ($1.60 / 12).

In this scenario, the fiberglass is the more cost-effective choice for achieving that specific R-value. Always do this simple math based on your local store’s current pricing to find the true value.

How to Choose the Right Insulation for Your Garage

The “best” insulation depends entirely on your priorities. For the highest R-value in a limited space, foil-faced polyisocyanurate rigid foam is a top performer. For a balance of good thermal performance, sound dampening, and DIY-friendly installation, mineral wool batt is an excellent all-around choice.

- Choose Rigid Foam Board (Polyiso or XPS) if: Your top priority is an extremely high R-value in thin walls (like 2x4s), or if your garage has concrete walls or is in a damp environment.

- Choose Batt Insulation (Mineral Wool or Fiberglass) if: Ease of DIY installation, sound dampening for a workshop, fire resistance (especially mineral wool), and initial cost-effectiveness are your main concerns.

For many garage enthusiasts, the ultimate answer may be a hybrid approach. You could use moisture-resistant XPS foam against a concrete foundation wall and then build a stud wall in front of it filled with high-performance mineral wool batt.

By understanding the unique strengths of each type, you can design a custom insulation system that will keep your garage comfortable, quiet, and functional for years to come.

Learn more about creating a complete climate solution with a garage heater here: The Complete Guide to Choosing a Garage Heater (opens in a new window).

Explore a deeper comparison of all insulation types in our article: Garage Insulation Choices: Batt, Spray, or Blown?